Selecting materials

The process of shoemaking at International shoes Co.,Ltd. begins with selecting leather to be used for the upper of the shoes.

The first important point we have to take into our consideration to pick out the best leather is the image of what the finished shoes look like. From the shape and fit of the shoes to how well and how long our clients can enjoy it, we fully use our imagination and professional experience to select leather which can bring the best result. Therefore it is not unusual for our experts to make suggestion about better choice of leather to help our clients’ desingers to realize their ideas.

The second impotant point is to choose the highest quality leather that barely has scrathes on. Our experts said, “We pay special attention on the leather which to be used for upper of shoes and be extremely careful when we select it because hidden scrathes can show up during one of the production process where the leather needs to be stretched. Among all the other leather products, leather shoes is the only one which requires this process during its production. Therefore selecting leather for shoes is tricker as we have to actually strech them to check and imagine how they turn into during production process and how they end up as finished pruducts.” Accordingly, for each shoes, we selected most suitable leather which can perform the best during production process and also as a finished product.

Cutting I

Cutting leatehr is one of the most momentous process of shoemaking. It is not too much to say that how well the leather is cut in this process decides the quality of finished product. In fact, in UK., professional leather cutter is considerd to be a noble occupation so they are held in high esteem.

And we are no extention on that point. We place much emphasis on cutting leather which to be used for upper of shoes especially because we endeavor to cut them avoiding having small scratches on. The most thorough we are to cut leatehr pieces without scratches, the less defacts to be found during later production process, and the less work and effort to be wasted. Because we, International Shoes, attributes our success to effective teamwork and mutual understanding and trust, we all do our own best not only to create a perfect pair of shoes but also to contribute to the team, so we are not willing to do anything that waste other teammates’ work. Futhermore, we are not willing to waste leather. Instead of pursing efficiency, we would like show our tremendous gratitude towards animals and tanneries.

Cutting II

At the International Shoes,the leather piece for certain parts can only be hand-cut our experts based on cardbord patterns. As our experts says, “This is something that machine can’t do.” Only well-experienced professional with exclusive skill can perform this succesfully because it requires exceptional skills which is capable to turn the shape of two dimensional cardboard pattern into there dimensional shape on the leather. They know how to stretch leather, to draw line on it, and to cut all the parts symmertically by taking flexibility and thickness of the leather into account. Yes, it takes much time and lot of detail works but that is what makes our shoes very unique and special.

High quality standard for invisible parts

We are committed to quality of our products and we evev set the same high quality standard for its invisible parts. Let’s take edge dyeing of leather for example. Even though the edge of the leather can be barely seen in the finished product, we still hand dye it for better appearance. Heel counters are also invisible part but we take our time and use leather to make it. Soak leather for several hours, and after dry it, soffen up a little and then it will be combines with upper shoes.

Less and less shoemakers use this type of leather heel counter these days. Instead, most of shoemakers use plastic heel counter for low production cost and high work efficiency. Although both type of heel counters have their own advantages, leather heel counter can perfectly attatched along the last shoe and produce exquisite silhouette. And last but not least, it will become more flexible and perform better fit for clients as they wear it over and over again. It is true that using leather heel counter is time consuming ant it costs more, but we are and we will be using leather heel counter because we believe that it is the best for our clients.

Sewing

At International Shoes, we carefully choose the best materials and method of sewing which can present the characteristics and impression of each shoes. For example, if we want to create elegant shoes, we sew it with stitches using thinner threads, and vice versa for casual shoes. We consider even one single stitch as a part of a design of our shoes.

As our experts sew our shoes in the rhythm of their heatbeat,. sewing is not just a process of shoemaking. You can feel their warm heart and lively beat of their passion in each stitches. Beauty of commodities made by machine less in homogeneity; while beauty of sweater hand-knitted by your grandma exists with warmth of her heart because it cintains the passion she embraces. Being precise is very important in shoemaking, but we also cherish warmth and vitality of handmade products so we keep our shoes with devotion in each stitches.

「We pursue comfortable shoes」

Lasting

Bottoming is the process that needs skills and lasting is the most sensitive step. After using Toe Laster to pull over the upper leather roughly, experts of International shoes make fine adjustments carefully by hand to make shoes symmetrical and balanced. Especially shoes with high shaft, such as long boots are essential to have a beautiful silhouette, Experts of International shoes take best advantage of the skills of lasting, to make our shoes beautiful and comfortable at the same time.

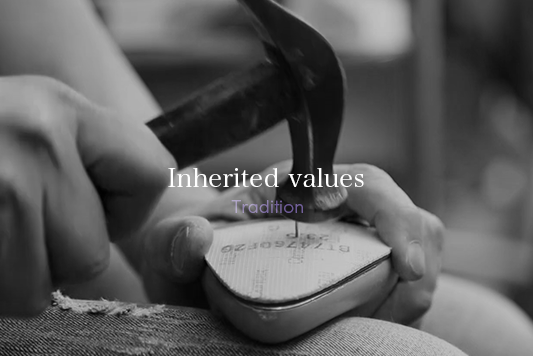

Heel Attaching

Heels are attached to the sole by small nails. Generally heels are nailed without a shoe last, but International Shoes adoptaspecial way. We nail with the shoe last inside, through this method the gap between sole and heel is reduced. This enables to make our heels more comfortable and durable. International shoes adhere to our principles, we use the shoe last with a hole to keep the mold inside shoes while we are attaching heels. This needs more cost and labor, however we aim at perfection to make high quality shoes.

「Shoemaking Process Known as Nesting」

Confirmation of the insole

One of the most important steps during the finishing is checking the soles. During the process of shoe making, nails are often used to attach vamps and soles. Nails rarely stick out of insoles. Therefore the shoes will not move to the next finishing step, when insole has any slight of uncomfortable indications. International Shoes knows that we cannot be too careful to prove worthy of our clients’ trust and checks insoles one by one on account of our clients.

Ironing Finish

Heating and ironing finish make shoes beautiful to shrink the leather and to get rid of the small wrinkles. This transformation can make the leather into beautiful commodity from the material.

However the heat is difficult to control and the leather is so delicate, and the Experts of International Shoes have evolved from many years of experience and create the shoes perfection carefully by ironing out the each leather.

Inspection before Case Packing

Before packing, strict quality controls were conducted. We are proud of the inspection with craftsmanship, because this promises the clients to the greater satisfaction than its actual price.

Shoemaking process

Those steps are just a few part of the shoemaking processes. A quality shoes undergoes numerous stages of production before it is completed. The precise number of steps involved varies drastically. This method of division of labor is known as nesting.

We International Shoes always promise a perfect fit, which elevates wearing comfort and their feet health. We are working for the moment to see our clients’ smile with our shoes.